GR80K – un broyeur de déchets compact et peu coûteux

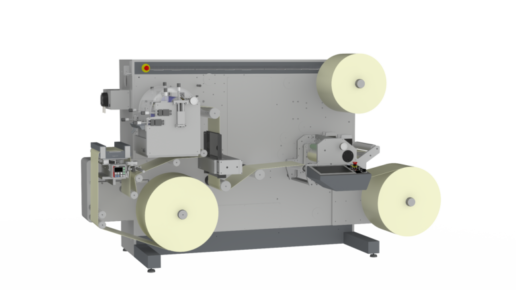

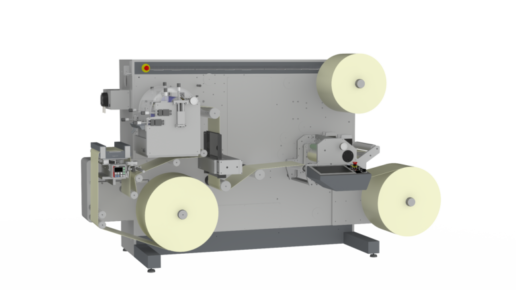

Installation MINI

Installation MINI

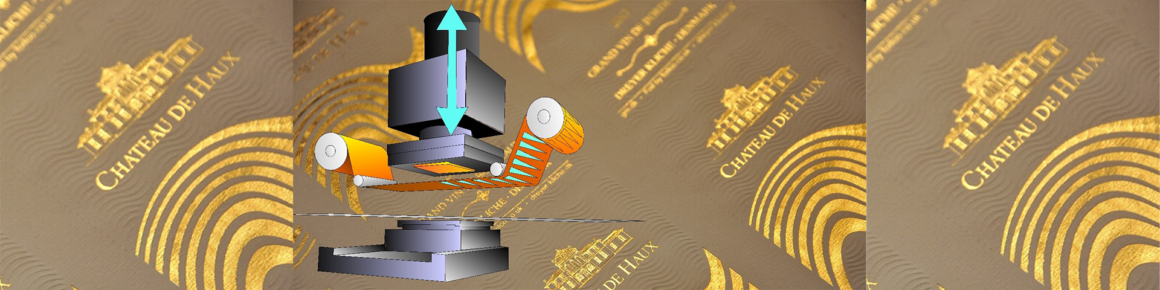

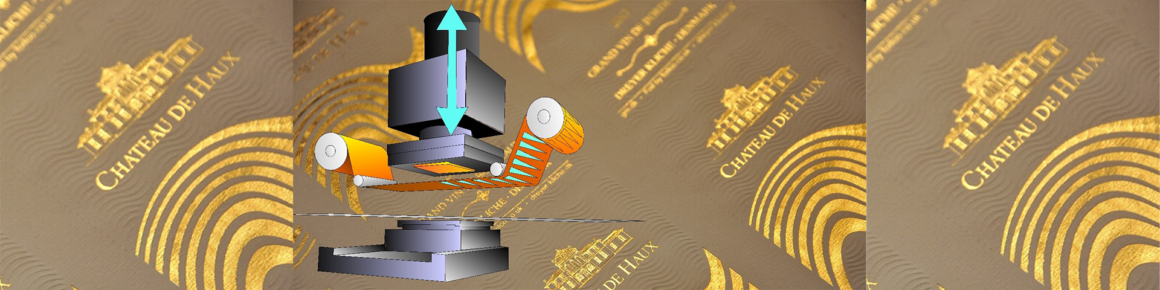

Dorure 3D

Dorure 3D

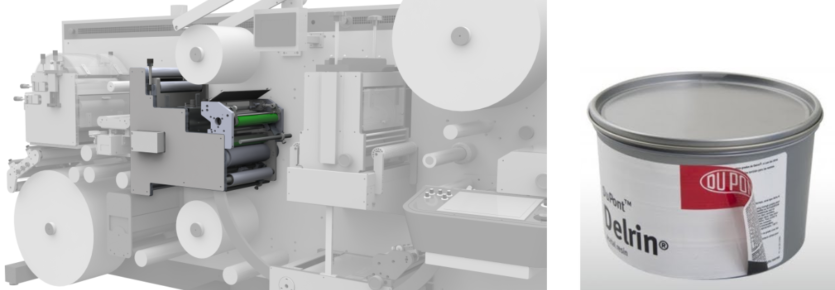

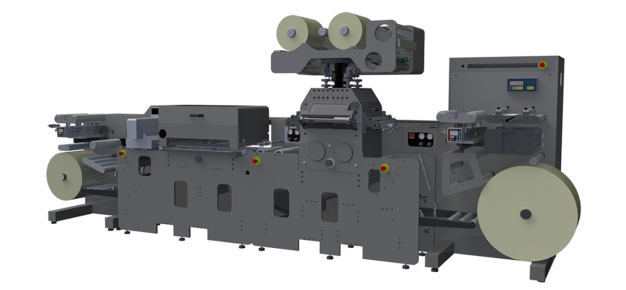

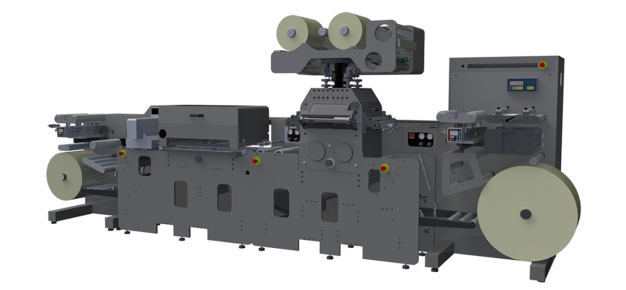

HF330

HF330

Une excellente solution qui permet de découper à 200 m/ min (656 ft/ min)

Une excellente solution qui permet de découper à 200 m/ min (656 ft/ min)

La découpe à grande vitesse révolutionne l'industrie de l'étiquette

La découpe à grande vitesse révolutionne l'industrie de l'étiquette

LC350 - Une machine de finition laser entièrement numérique

LC350 - Une machine de finition laser entièrement numérique

CC160/ 200S - votre solution de mandrins à la demande

CC160/ 200S - votre solution de mandrins à la demande

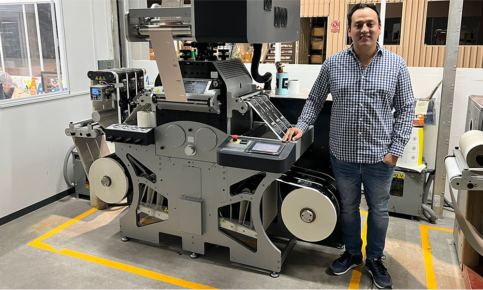

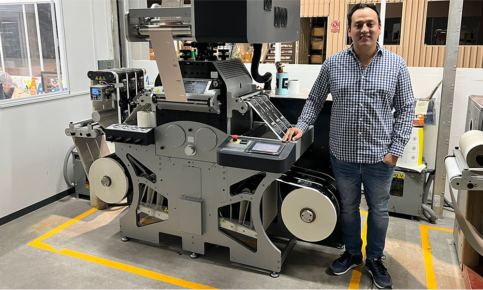

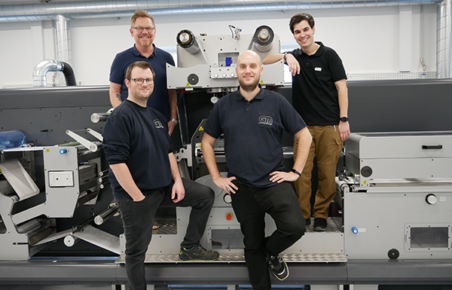

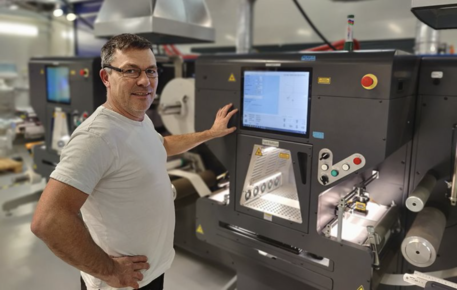

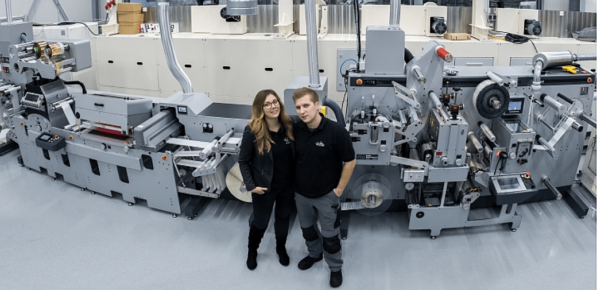

Eticom double sa capacité d'embellissement avec GM

Eticom double sa capacité d'embellissement avec GM

LC350 est la machine de finition laser entièrement

LC350 est la machine de finition laser entièrement

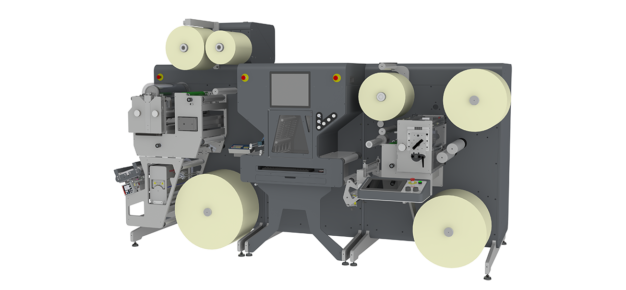

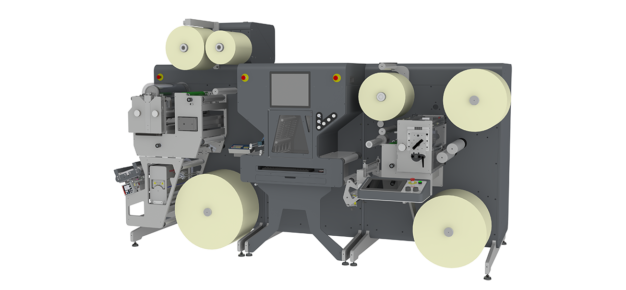

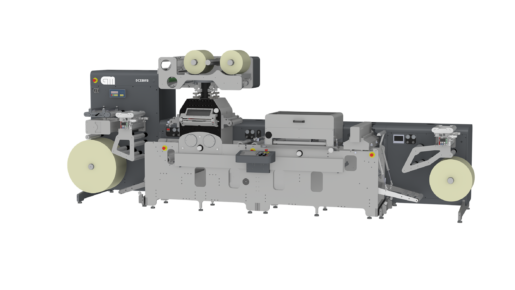

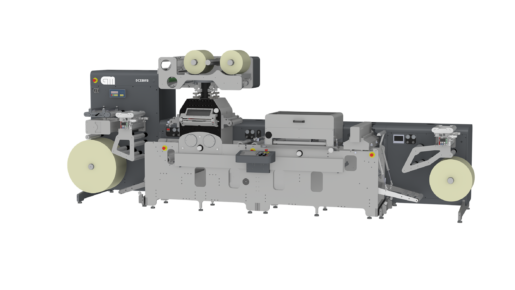

La gamme DC350Flex+ Wine fera ressortir vos étiquettes dans une mer d'options de vin. La ligne DC350Flex+ Wine est une ligne de finition haut de gamme qui offre le meilleur de la finition rapide et hautement automatisée du vin.

La gamme DC350Flex+ Wine fera ressortir vos étiquettes dans une mer d'options de vin. La ligne DC350Flex+ Wine est une ligne de finition haut de gamme qui offre le meilleur de la finition rapide et hautement automatisée du vin.

Cassette de refente à réglage rapide

Cassette de refente à réglage rapide

La nouvelle SemiTurret est une enrouleuse non-stop GM spécialement conçue pour un changement rapide de tâche dans la finition d'étiquettes. Cela peut non seulement vous faire gagner du temps, mais également éliminer 2 à 3 % de déchets sur vos étiquettes à court tirage.

La nouvelle SemiTurret est une enrouleuse non-stop GM spécialement conçue pour un changement rapide de tâche dans la finition d'étiquettes. Cela peut non seulement vous faire gagner du temps, mais également éliminer 2 à 3 % de déchets sur vos étiquettes à court tirage.

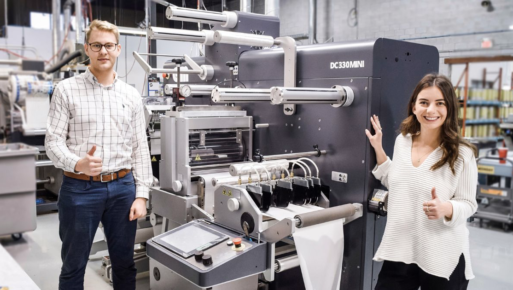

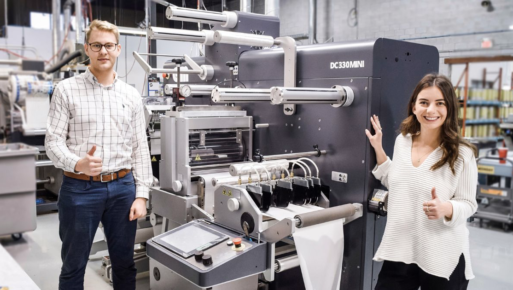

DC330Mini Nouvelle vidéo

DC330Mini Nouvelle vidéo

LC350 est un excellent choix pour toute presse d'étiquettes numérique

LC350 est un excellent choix pour toute presse d'étiquettes numérique

Parlons profit dans la finition d'étiquettes

Parlons profit dans la finition d'étiquettes

Intégration partenaire CERM-GM : Automatisation de la collecte de données

Intégration partenaire CERM-GM : Automatisation de la collecte de données

Cette vidéo montre une manière unique d'utiliser notre technologie de finition.

Cette vidéo montre une manière unique d'utiliser notre technologie de finition.

L'étiquette multicouche est une technologie innovante que seuls quelques imprimeurs peuvent offrir à leurs clients.

L'étiquette multicouche est une technologie innovante que seuls quelques imprimeurs peuvent offrir à leurs clients.

Dans ce processus, il n'y a pas de flexo ni de cliché - tout le dorure se fait de manière numérique !

Voyez comment nous procédons dans cette vidéo - présentée par Uffe Nielsen directement depuis notre Democentre.

Dans ce processus, il n'y a pas de flexo ni de cliché - tout le dorure se fait de manière numérique !

Voyez comment nous procédons dans cette vidéo - présentée par Uffe Nielsen directement depuis notre Democentre.

Vidéo de la nouvelle usine

Vidéo de la nouvelle usine

AEROLED

AEROLED

Vernis jet d'encre DVM350

Vernis jet d'encre DVM350

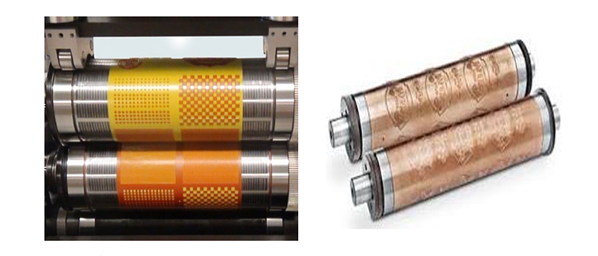

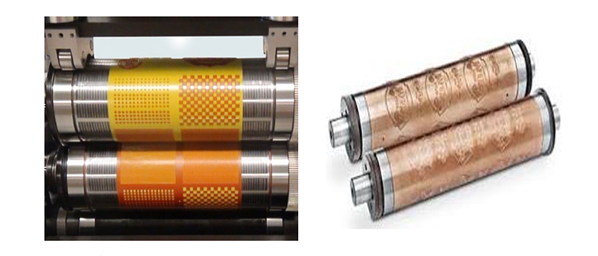

Outil pour. Dorure à Chaud et Gaufrage

Outil pour. Dorure à Chaud et Gaufrage

Le bon investissement dans la finition des étiquettes a été supplémentaire pour Hulco Printers, Inc.

Le bon investissement dans la finition des étiquettes a été supplémentaire pour Hulco Printers, Inc.

Boîte de refente automatique - SmartSlit

Boîte de refente automatique - SmartSlit

Des solutions plus écologiques : les LED UV sont désormais disponibles comme alternative aux lampes UV au mercure.

Des solutions plus écologiques : les LED UV sont désormais disponibles comme alternative aux lampes UV au mercure.

SONNENTOR investit dans une production interne efficace d'étiquettes

SONNENTOR investit dans une production interne efficace d'étiquettes

Dorure à froid

Dorure à froid

Découvrez comment nous avons créé une étiquette de Noël avec de nombreuses fonctionnalités. Dans cette vidéo, nous montrons la dorure à chaud, le gaufrage et la sérigraphie sur le DE350 et la découpe finale sur le LC350.

Découvrez comment nous avons créé une étiquette de Noël avec de nombreuses fonctionnalités. Dans cette vidéo, nous montrons la dorure à chaud, le gaufrage et la sérigraphie sur le DE350 et la découpe finale sur le LC350.

Découvrez comment passer d'un rouleau d'étiquettes à des étiquettes en feuilles avec la rameuse CS350 - la dernière rameuseà guillotine rouleau à feuille de GM.

Découvrez comment passer d'un rouleau d'étiquettes à des étiquettes en feuilles avec la rameuse CS350 - la dernière rameuseà guillotine rouleau à feuille de GM.

La société Pscherer GmbH fait confiance à la technologie GM ainsi qu'au service professionnel de Nilpeter.

La société Pscherer GmbH fait confiance à la technologie GM ainsi qu'au service professionnel de Nilpeter.

Comment préparer l'outil combiné pour l'embellissement

Comment préparer l'outil combiné pour l'embellissement

Inspection d'impression d'étiquettes à 100 % démontrée sur la bobineuse d'inspection de refendeuse SR350

Inspection d'impression d'étiquettes à 100 % démontrée sur la bobineuse d'inspection de refendeuse SR350

GM Smart Load - Chargeur automatique de plaques de découpe

GM Smart Load - Chargeur automatique de plaques de découpe

LP2i Étiquettes étend ses capacités d'embellissement

LP2i Étiquettes étend ses capacités d'embellissement

Dans cette vidéo YouTube inédite, Uffe vous explique comment retirer un cylindre découpé à l'emporte-pièce. Agréable et facile avec l'aide du GM RL Roll Lifter !

Dans cette vidéo YouTube inédite, Uffe vous explique comment retirer un cylindre découpé à l'emporte-pièce. Agréable et facile avec l'aide du GM RL Roll Lifter !

Concevez et créez des étiquettes uniques avec des trous qui permettent la présentation du produit à l'intérieur de l'emballage.

Concevez et créez des étiquettes uniques avec des trous qui permettent la présentation du produit à l'intérieur de l'emballage.

Le DC350NANO est désormais capable de fonctionner à 130 m/min à pleine vitesse de rotation. Cela augmente la productivité et signifie que l'unité peut correspondre à n'importe quelle presse numérique sur le marché.

Le DC350NANO est désormais capable de fonctionner à 130 m/min à pleine vitesse de rotation. Cela augmente la productivité et signifie que l'unité peut correspondre à n'importe quelle presse numérique sur le marché.

Dorure à chaud haute vitesse

Dorure à chaud haute vitesse

Le groupe Barthel mise sur la fiabilité et la précision avec sa nouvelle ligne de transformation GM

Le groupe Barthel mise sur la fiabilité et la précision avec sa nouvelle ligne de transformation GM

Installation nouvelle LR250

Installation nouvelle LR250

Option d'économie de dorure à chaud GM Multistep

Option d'économie de dorure à chaud GM Multistep

Etiquette multicouche - Une étiquette de grande valeur avec de nombreux avantages

Etiquette multicouche - Une étiquette de grande valeur avec de nombreux avantages

40 ans

40 ans

Nouvelle installation DC330MINI

Nouvelle installation DC330MINI

LC350

LC350

Augmentation de la vitesse: Nous avons augmenté la vitesse du DC330MINI de 65 à 80 m / min en semi-rotatif et de 72 m / min à 130 m / m en mode entièrement rotatif.

Augmentation de la vitesse: Nous avons augmenté la vitesse du DC330MINI de 65 à 80 m / min en semi-rotatif et de 72 m / min à 130 m / m en mode entièrement rotatif.

DC350 en ligne avec une HP INDIGO

DC350 en ligne avec une HP INDIGO

Broyeur de déchets GR100

Broyeur de déchets GR100

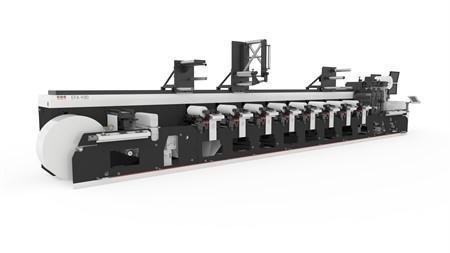

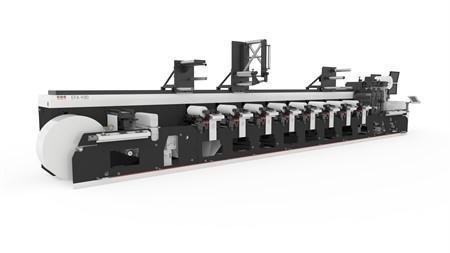

Alu-Lids achète la première presse flexo MPS pour augmenter la production de couvercles en aluminium

Alu-Lids achète la première presse flexo MPS pour augmenter la production de couvercles en aluminium

Le gaufrage est l'un des nombreux processus d'embellissement utilisés dans l'impression qui donne aux étiquettes un aspect unique et attrayant avec une image ou un motif en relief

Le gaufrage est l'un des nombreux processus d'embellissement utilisés dans l'impression qui donne aux étiquettes un aspect unique et attrayant avec une image ou un motif en relief

Entretien avec Uffe Nielsen dans le hall de production

Entretien avec Uffe Nielsen dans le hall de production

Nouvelle Usine

Nouvelle Usine

Convertisseur GM avec CERM installé chez Interket

Convertisseur GM avec CERM installé chez Interket

GM Demo Center est maintenant entièrement équipé et opérationnel

GM Demo Center est maintenant entièrement équipé et opérationnel

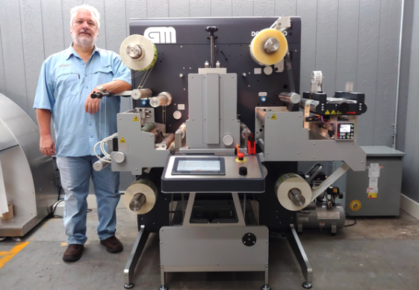

Cambridge Label installe une DC330 MINI sans aide

Cambridge Label installe une DC330 MINI sans aide

Guide du nouveau laser LC350

Guide du nouveau laser LC350

Histoires de DC330MINI & DC330MINIflex sur le marché Américain

Histoires de DC330MINI & DC330MINIflex sur le marché Américain

Le mois dernier, nous avons lancé la campagne HOTFB330 sur LinkedIn et pour cette raison, nous avons créé une autre page de destination dédiée. Consultez les informations et regardez les vidéos, partagez-les avec vos clients. Cliquez simplement sur l'image ci-dessous.

Le mois dernier, nous avons lancé la campagne HOTFB330 sur LinkedIn et pour cette raison, nous avons créé une autre page de destination dédiée. Consultez les informations et regardez les vidéos, partagez-les avec vos clients. Cliquez simplement sur l'image ci-dessous.

Renforcement des relations entre Epson et GM

Renforcement des relations entre Epson et GM

Installation d'une découpe laser LC350 chez Coloplast

Installation d'une découpe laser LC350 chez Coloplast

Installation DC330 NANO en Italie

Installation DC330 NANO en Italie

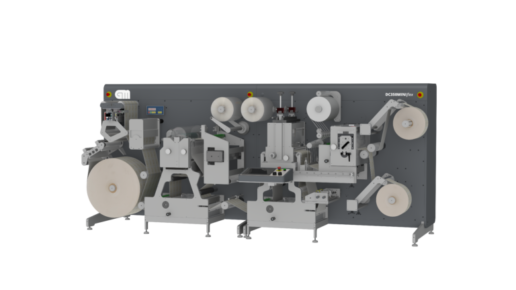

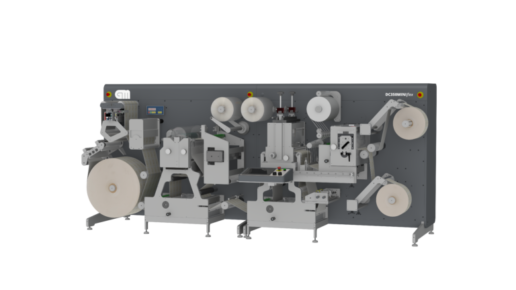

Le LC350 rejoint le portefeuille en expansion de GM de lignes de conversion capables de produire des étiquettes dans une largeur de bande de 350 mm. Il s'agit d'une machine de finition laser compacte, rentable et entièrement numérique, qui offre une finition d'étiquettes complexe avec une qualité de coupe supérieure, un vernissage et un vernissage ponctuel avec le module semi-rotatif SmartFlexo, ainsi que la plastification, la dorure à froid, la refente de bande et le double rembobinage. . Parmi les autres options, citons le dispositif de traitement Corona, le module de refendage SmartSlit avec système de positionnement automatique des couteaux et un lecteur de code-barres pour un changement de travail rapide ou un rappel rapide des travaux existants.

Le LC350 rejoint le portefeuille en expansion de GM de lignes de conversion capables de produire des étiquettes dans une largeur de bande de 350 mm. Il s'agit d'une machine de finition laser compacte, rentable et entièrement numérique, qui offre une finition d'étiquettes complexe avec une qualité de coupe supérieure, un vernissage et un vernissage ponctuel avec le module semi-rotatif SmartFlexo, ainsi que la plastification, la dorure à froid, la refente de bande et le double rembobinage. . Parmi les autres options, citons le dispositif de traitement Corona, le module de refendage SmartSlit avec système de positionnement automatique des couteaux et un lecteur de code-barres pour un changement de travail rapide ou un rappel rapide des travaux existants.

Le GM EB30 EBEAM est une solution innovante de revêtement sélectif ou d'enduction en ligne ou hors ligne pour les bandes imprimées numériquement de 30 pouces de largeur. Elle est 100% modulaire et conçue pour une intégration parfaite avec la presse numérique HP Indigo 20000. Le GM EB30 offre un revêtement de pointe. Tous les vernis EBEAM, à base d'eau et UV peuvent être utilisés pour une large gamme d'applications, y compris les produits pharmaceutiques, les médias, les aliments et la confiserie, les cosmétiques, l'électronique grand public, la promotion, les cadeaux, etc.

Le GM EB30 EBEAM est une solution innovante de revêtement sélectif ou d'enduction en ligne ou hors ligne pour les bandes imprimées numériquement de 30 pouces de largeur. Elle est 100% modulaire et conçue pour une intégration parfaite avec la presse numérique HP Indigo 20000. Le GM EB30 offre un revêtement de pointe. Tous les vernis EBEAM, à base d'eau et UV peuvent être utilisés pour une large gamme d'applications, y compris les produits pharmaceutiques, les médias, les aliments et la confiserie, les cosmétiques, l'électronique grand public, la promotion, les cadeaux, etc.

Le DC350 avec l'unité de film chaud ultra-rapide de Pantec est prêt pour de nouveaux défis. Regardez la vidéo et découvrez de nouvelles opportunités pour la production de vos étiquettes.

Le DC350 avec l'unité de film chaud ultra-rapide de Pantec est prêt pour de nouveaux défis. Regardez la vidéo et découvrez de nouvelles opportunités pour la production de vos étiquettes.

Dérouleur Martin sur MPS

Dérouleur Martin sur MPS

Machine pour imprimer de l'Aluminium

Machine pour imprimer de l'Aluminium

Watch the video and see how we make labels with holes in, using laser die-cutter and

the special module that removes the waste stickers from the web.

Watch the video and see how we make labels with holes in, using laser die-cutter and

the special module that removes the waste stickers from the web.

Get the best in fast and automated converting in 550 mm web width. Build with semi-rotation

in varnish and die-cutting as standard. Upgrade with value options...

Get the best in fast and automated converting in 550 mm web width. Build with semi-rotation

in varnish and die-cutting as standard. Upgrade with value options...

Encore plus de possibilités que la DC330MINIFLEX

Encore plus de possibilités que la DC330MINIFLEX

The GM Double Speed Die is our latest module for fast die-cutting working at a maximum speed of up to 140 m/min.

The GM Double Speed Die is our latest module for fast die-cutting working at a maximum speed of up to 140 m/min.

What Cast'n'cure is about? What types of foil can be used? How to get the super gloss,

soft matt touch or holographic effects using label converting machine? Watch the video...

What Cast'n'cure is about? What types of foil can be used? How to get the super gloss,

soft matt touch or holographic effects using label converting machine? Watch the video...

The NEW Premium Wine Label Line - the 330FB. Impress your customers with a great combination of beauty and highest quality. The 330FB is a precision, 50-ton pressure heavy-duty, stamping unit for production of high-quality labels. The machine can do foil stamping, embossing or one pass foil and embossing, and high-build screen printing. Watch video here:

The NEW Premium Wine Label Line - the 330FB. Impress your customers with a great combination of beauty and highest quality. The 330FB is a precision, 50-ton pressure heavy-duty, stamping unit for production of high-quality labels. The machine can do foil stamping, embossing or one pass foil and embossing, and high-build screen printing. Watch video here:

Grafiprint was born in 2006 from the idea of Fabio Piacentino to create a digital printing centre with an adjacent graphics studio. The goal was to become a reference partner for Sicilian entrepreneurship, providing products and services of refined quality...

Grafiprint was born in 2006 from the idea of Fabio Piacentino to create a digital printing centre with an adjacent graphics studio. The goal was to become a reference partner for Sicilian entrepreneurship, providing products and services of refined quality...

Comment éviter les mandrins en cartons à l'échenillage

Comment éviter les mandrins en cartons à l'échenillage

Avez-vous besoin de cet avantage supplémentaire pour le vin ou l'étiquette cosmétique? Jetez un œil à cette photo d'atelier de notre ligne d'embellissement 330FB pour étiquettes. Cette unité est entièrement servocommandée et dispose de commandes avancées telles que "dwell time" et "foil saver".

Avez-vous besoin de cet avantage supplémentaire pour le vin ou l'étiquette cosmétique? Jetez un œil à cette photo d'atelier de notre ligne d'embellissement 330FB pour étiquettes. Cette unité est entièrement servocommandée et dispose de commandes avancées telles que "dwell time" et "foil saver".

NOUVEAU SR350 - le nouveau bobineur-refendeur à grande vitesse GM avec inspection. La machine est équipée de l'option avancée de système d'inspection d'étiquettes Nikka M1 +. Il accélère jusqu'à 300 m / min en quelques secondes et s'arrête précisément à moins de 10 cm si une erreur est détectée.

NOUVEAU SR350 - le nouveau bobineur-refendeur à grande vitesse GM avec inspection. La machine est équipée de l'option avancée de système d'inspection d'étiquettes Nikka M1 +. Il accélère jusqu'à 300 m / min en quelques secondes et s'arrête précisément à moins de 10 cm si une erreur est détectée.

MPS and Domino to launch wider hybrid EF SYMJET press at Labelexpo Europe

MPS and Domino to launch wider hybrid EF SYMJET press at Labelexpo Europe

Mercury Walch invested in DC330MINI, and the supply and installation of the machine were provided by Aldus Tronics - GM distributor in Australia.

Mercury Walch is Tasmania’s leading producer of printed materials including labels, packaging, commercial print and mail and has a history dating back to the late 1800s.

Gary Nilsson, General Manager says: "After many months of research and viewing quite a number of different finishing options, Mercury Walch chose the DC330MINI as its main new piece of finishing equipment for our label division..."

Mercury Walch invested in DC330MINI, and the supply and installation of the machine were provided by Aldus Tronics - GM distributor in Australia.

Mercury Walch is Tasmania’s leading producer of printed materials including labels, packaging, commercial print and mail and has a history dating back to the late 1800s.

Gary Nilsson, General Manager says: "After many months of research and viewing quite a number of different finishing options, Mercury Walch chose the DC330MINI as its main new piece of finishing equipment for our label division..."

GapMaster is the world’s leading system for setting gaps while machines are running. Based on an anvil cylinder, the system is used to adjust the gap between the anvil body and the magnetic or cutting cylinder in ultra-precise steps (the smallest step is 0.8 µm). This means that the machine operator can safely process materials with varying substrate thicknesses. The permanent high-precision setting reduces cutting tool wear and significantly extends tool life.

GM offers GapMaster to all existing diecutting machines.

GapMaster is the world’s leading system for setting gaps while machines are running. Based on an anvil cylinder, the system is used to adjust the gap between the anvil body and the magnetic or cutting cylinder in ultra-precise steps (the smallest step is 0.8 µm). This means that the machine operator can safely process materials with varying substrate thicknesses. The permanent high-precision setting reduces cutting tool wear and significantly extends tool life.

GM offers GapMaster to all existing diecutting machines.

We look forward to see you and your clients at our stand 9A40. Below is the updated list of the machines and solutions that we will show at the event:

• NEW DC350 V3 with NEW Smart Turret, NEW Smart Loading and NEW Smart Stripping modules

• NEW 330FB V3 - Hot Foil and Screen – With NEW Faster screen printing unit

• NEW DC330MINI V4 stand-alone and in-line with inkjet press

• NEW SR350 - New fast slitter-rewinder - 300m/min – With Nikka inspection

• DC330 in-line with Inkjet

• GM Dashboard workflow software

• ETV330

• PNT160

We look forward to see you and your clients at our stand 9A40. Below is the updated list of the machines and solutions that we will show at the event:

• NEW DC350 V3 with NEW Smart Turret, NEW Smart Loading and NEW Smart Stripping modules

• NEW 330FB V3 - Hot Foil and Screen – With NEW Faster screen printing unit

• NEW DC330MINI V4 stand-alone and in-line with inkjet press

• NEW SR350 - New fast slitter-rewinder - 300m/min – With Nikka inspection

• DC330 in-line with Inkjet

• GM Dashboard workflow software

• ETV330

• PNT160

South African printer invested in an MPS EFS 430 press via Rotocon

South African printer invested in an MPS EFS 430 press via Rotocon

MPS présente les gammes de presses flexo EFS et EFA: «Avec un beau design, de nouvelles couleurs et des innovations encore plus conviviales, les presses flexo EFS et EFA sont le prochain niveau exigé par ce marché», a déclaré Atze Bosma, PDG de MPS Systems.

MPS présente les gammes de presses flexo EFS et EFA: «Avec un beau design, de nouvelles couleurs et des innovations encore plus conviviales, les presses flexo EFS et EFA sont le prochain niveau exigé par ce marché», a déclaré Atze Bosma, PDG de MPS Systems.

Nouvelle Vidéo MINIflex

Nouvelle Vidéo MINIflex

Smartlam. Did you Know?

The SmartLam unit works by stretching the top layer between two nips. This means that the top layer must be made out of stretchable material, for example PE/PP. In order for the unit to work properly, the top web must be printed slightly shorter than the bottom web. By controlling the speed of the SmartLam nip it is possible to stretch the top layer into place.

E.g. by running the SmartLam nip at the same speed as the central nip, the top layer will be drifting since it was printed shorter than the bottom layer. Likewise, if we run the SmartLam nip slower than the central nip, we will stretch the top layer into the place. An algorithm calculates the needed speed difference, depending on the repeat length and how much shorter the top layer has been printed...

Smartlam. Did you Know?

The SmartLam unit works by stretching the top layer between two nips. This means that the top layer must be made out of stretchable material, for example PE/PP. In order for the unit to work properly, the top web must be printed slightly shorter than the bottom web. By controlling the speed of the SmartLam nip it is possible to stretch the top layer into place.

E.g. by running the SmartLam nip at the same speed as the central nip, the top layer will be drifting since it was printed shorter than the bottom layer. Likewise, if we run the SmartLam nip slower than the central nip, we will stretch the top layer into the place. An algorithm calculates the needed speed difference, depending on the repeat length and how much shorter the top layer has been printed...

We are MPS

We are MPS

We look forward to see you and your clients at our stand 9A40.

We look forward to see you and your clients at our stand 9A40.

Hot stamping or foil stamping is a printing method of relief printing which pre-dried ink or foils are transferred to a surface at high temperatures. The non-polluting method has diversified since its rise to prominence in the 19th century to include a variety of colours and processes...

Hot stamping or foil stamping is a printing method of relief printing which pre-dried ink or foils are transferred to a surface at high temperatures. The non-polluting method has diversified since its rise to prominence in the 19th century to include a variety of colours and processes...

The GM 330FB Hot Foil and Screen has been sold recently to IKONPRINT in Denmark

The GM 330FB Hot Foil and Screen has been sold recently to IKONPRINT in Denmark

We are MPS

We are MPS

EDNN - MPS EF SYMJET hybrid press

EDNN - MPS EF SYMJET hybrid press

talk to me - connectivity by MPS

talk to me - connectivity by MPS

Meyer - MPS EF SYMJET - powered by Domino

Meyer - MPS EF SYMJET - powered by Domino

GM 330FB Hotfoil and Screen print line

newest video

GM 330FB Hotfoil and Screen print line

newest video

MPS confirme la vente et l'installation d'une autre presse hybride EF SYMJET sur l'imprimeur canadien ASL Print FX

MPS confirme la vente et l'installation d'une autre presse hybride EF SYMJET sur l'imprimeur canadien ASL Print FX

GM 330FB premium label finisher installed in Nova Scotia

GM 330FB premium label finisher installed in Nova Scotia

Russian label printer Evroflex installs their sixth MPS flexo press

Russian label printer Evroflex installs their sixth MPS flexo press

Papier-Schäfer invests in impressive GM converters line

Papier-Schäfer invests in impressive GM converters line

The printing house from Houston in Texas, founded in 1963 invests in DC330Mini finisher for their digital production system

The printing house from Houston in Texas, founded in 1963 invests in DC330Mini finisher for their digital production system

Doublez la vitesse de Découpe semi rotative

Doublez la vitesse de Découpe semi rotative